- Home

- Technology & Plants

- Paraformaldehyde Plant

Paraformaldehyde Plant

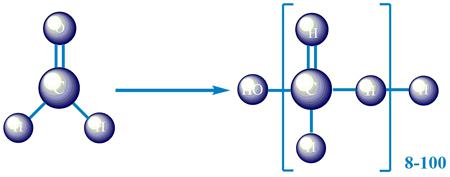

Paraformaldehyde is a product of the dehydration polycondensation reaction of formaldehyde solution, also called dimethoxymethane. There are mainly two types: low polymerization degree paraformaldehyde (degree of polymerization is 2-8), and paraformaldehyde (degree of polymerization is 8-100).

Helipont provides the necessary technologies for both paraformaldehyde solutions, including the processing plan, special equipment and catalyst.

Production Process

Vacuum Drying ProcessFirstly, increase the formaldehyde concentration from 37% to 65% through concentrated dehydration, then put it into rake dryers for further dehydration, until when the paraformaldehyde become a solid powder. The entire dehydration process is operated under negative pressure. The evaporating condensate containing 10-15% formaldehyde will return to the formaldehyde section and can be used to produce methylal, urotropine or mixed to 37% formaldehyde for sale. It is a batch form operation. Each batch feed for rake dryers is around 4-5m3, drying time is 4-6 hours. The production cycle is long, while the production capacity is low, and the product is in the form of powder mixed block.

Vacuum Rake Dryer Paraformaldehyde Plant Project GalleryFormaldehyde concentration is increased to 80% after second-efficiency condensation under vacuum, and then pumped into the spraying cooling tower. The concentrated formaldehyde solution is sprayed through the nozzle and condensed into a granular paraformaldehyde solid. This process is consequent, the time needed is short, and the product has good solubility because of shorter formed formaldehyde chain.

Spray Dryer Paraformaldehyde Plant Project GalleryThe production capacity of vacuum drying process and spray drying process is similar, while vacuum drying process needs less investment and spray drying process can produce paraformaldehyde with higher quality.

Helipont is a solutions provider, implementing engineering, procurement, and construction (EPC) projects involving formaldehyde and formaldehyde derivative production operations. We focus innovative efforts on two areas: chemical equipment and chemical trade. Our silver catalyst formaldehyde production process and related equipment has been successfully implemented by some of the world’s premier chemical processors, helping them minimize operating costs and handle by-products safely and effectively.

Read More