- Home

- Technology & Plants

- UF MUF Resin Glue Plant

UF MUF Resin Glue Plant (Urea Formaldehyde and Melamine Urea Formaldehyde)

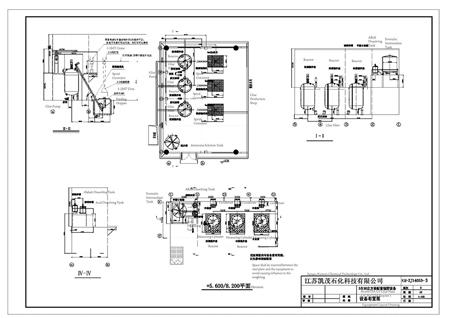

UF MUF resin glue plants are used to produce two adhesive types: UF (urea formaldehyde resin) and MUF (melamine modified urea formaldehyde resin). We supply artificial board manufacturers with the one stop services, from technical design and product design, all the way to equipment installation tests.

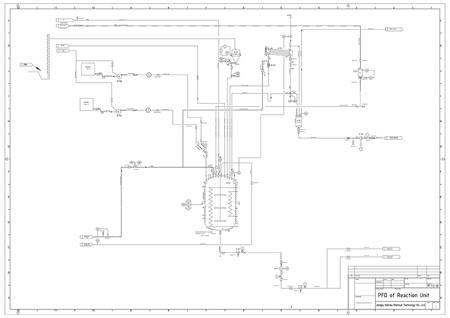

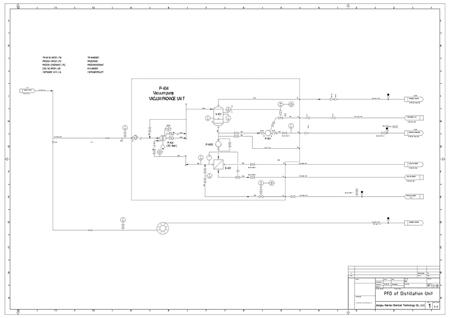

- Resin stirring kettle.

- High efficiency cooler.

- Electrical control system.

- Addition phase.

- First polycondensation.

- Second polycondensation.

- The amount of added Poly (vinyl alcohol), melamine, additives and ammonia, with PH value, temperature, reaction period and insulation period are different based on the needed glue environmental protection level and the matched wood material. Please be flexible in your decision.

- For more information on the production process, please do not hesitate to contact us.

| S/N | Item | Index | |||

| UF RESIN E2 | MUF RESIN E2 | UF RESIN E1 | UF RESIN E0 | ||

| 1 | Appearance | Semi opaque viscous liquid | |||

| 2 | Viscosity at 30 ° C | 200-250 cps | 200 cps | 50-200 | 180 cps |

| 3 | Solids Content at 2hr/120oC | 49-51% | 56% | 50-54% | 54% |

| 4 | Specific Gravity at 30oC | 1.180-1.200 | 1.21 | 1.18-1.20 | 1.205 |

| 5 | pH at 30oC | 8.0-9.0 | 8.75 | 7.0-8.0 | 9.00 |

| 6 | Gel time | 30-40 sec | 50 sec | 50-90 sec | 200 sec |

| Material / Utility | Value |

| Formaldehyde | 37%-52% |

| Urea | 46.5% |

| Melamine | 99.8% |

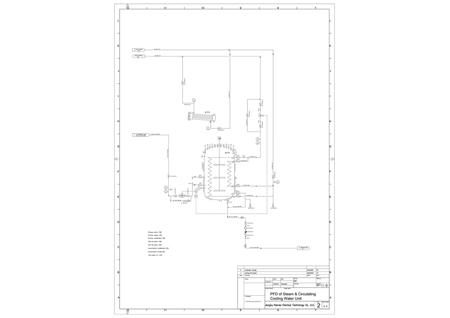

| Process water(spare) | 500kg/h |

| 0.3Mpa | |

| Colling water (required for cooling, intermittent supply) | 250m3/h |

| 31°C | |

| 0.3Mpa | |

| Low pressure steam (Required for start and dehydration, intermittent supply) | 2500kg/h |

| 0.6Mpa | |

| Instrument air | 28Nm3/h |

| 0.4Mpa | |

| Electrical power | install219kW |

| employ170kW |

Helipont is a solutions provider, implementing engineering, procurement, and construction (EPC) projects involving formaldehyde and formaldehyde derivative production operations. We focus innovative efforts on two areas: chemical equipment and chemical trade. Our silver catalyst formaldehyde production process and related equipment has been successfully implemented by some of the world’s premier chemical processors, helping them minimize operating costs and handle by-products safely and effectively.

Read More