- Home

- Technology & Plants

- DMMn Plant

DMMn Plant

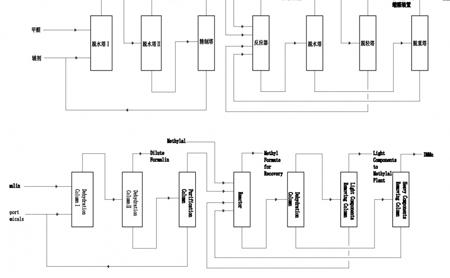

This process uses formaldehyde and methylal to synthesize DMMn. The plants provided by Helipont are composed of one set of methanol to formaldehyde plant, one set of methylal plant and one set of DMMn plant. A solid acid catalyst is used throughout the entire plant, giving it a long service life and allows for easy product separation. Using formaldehyde as the raw material can saves money when compared to paraformaldehyde or trioxane. Without the paraformaldehyde device and trioxane device, project costs are also significantly reduced and waste water meets first level emission standards.

- 50% concentration formaldehyde enters the climbing film evaporator to be concentrated to 75%.

- The mixed 75% formaldehyde and methylal react with each other to create DMMn and very little heavy by-product.

- Send Dmmn to purge gas absorption column to be dewatered.

Annotation: for more information, please do not hesitate to contact us.

| Project | Index |

| DMMn Content | >99.5% |

| Methanol | <0.5% |

| Methylal Content | <0.01% |

| Appearance | colorless, transparent |

| Sulfur Content | <1ppm |

| Chlorine Content/td> | <1ppm |

| Acidity | ≤7(mg KOH/100ml) |

| Particular | Consumption quota |

| Methanol | 1.4 t/t |

| Auxiliary Agent | 10 kg/t |

| Steam | 3.5 t/t |

| Process water | 1.2 t/t |

| Primary water | 6.3 t/t |

| Circulating water | 245.2 t/t |

| Industrial electricity | 200 kWh/t |

| Instrument air | ~32 Nm3/t |

| Nitrogen(purge) | ~60 Nm3/hr |

Helipont is a solutions provider, implementing engineering, procurement, and construction (EPC) projects involving formaldehyde and formaldehyde derivative production operations. We focus innovative efforts on two areas: chemical equipment and chemical trade. Our silver catalyst formaldehyde production process and related equipment has been successfully implemented by some of the world’s premier chemical processors, helping them minimize operating costs and handle by-products safely and effectively.

Read More