- Home

- Technology & Plants

- Acetaldehyde Plant

Acetaldehyde Plant

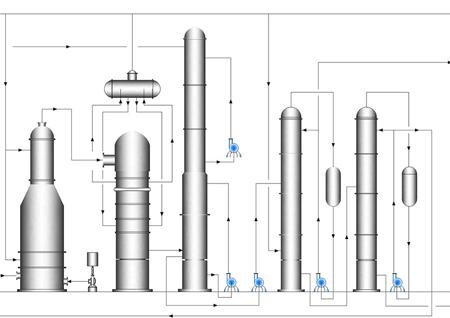

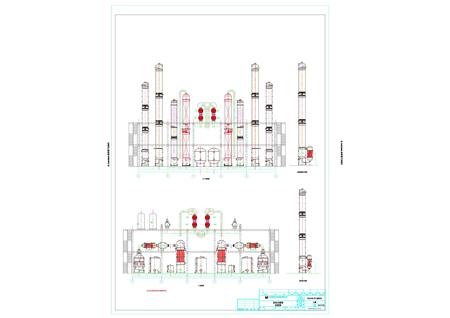

Acetaldehyde production includes 3 primary process: acetylene hydration, ethylene oxidation, and alcohol oxidation. Helipont currently utilizes the alcohol oxidation process for the production acetaldehyde, because alcohol features a low costs and a wide usage range. It also features a low conversion rate. We use double towers for absorption- one tower for circulation absorption, and the other for a spraying absorption and recycling plant in order to obtain the best consumption.

- Evaporator

- Roots blower

- Oxidation tower

- Absorption tower

- Mix the alcohol material.

- After removing impurities such as dust via air filter, the outside air enters the evaporator via the roots blower.

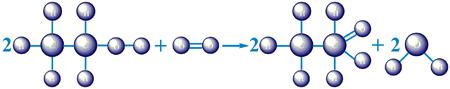

- Mixed alcohol and air react in the evaporator and generate acetaldehyde.

- Cool down the acetaldehyde and unreacted alcohol.

- Rectify the acetaldehyde.

Annotation: for more information, please do not hesitate to contact us.

Performance| Name | Specification and Composition | Consumption quota |

| Alcohol | ≥95% | 1.170t/t |

| Name | Specification and Composition | 4.3t/t |

| Process Water | 25PPM(5℃)Chloridion | 6t/t |

| Steam | 0.8MPa(Gauge) | 3.0t/t |

| Instrument Compressed Gas | 0.6MPa(Gauge) | 7m3/t |

| Circulating Cooling Water | Water Inlet30℃, Water Outlet38℃, Water Pressure 0.35MPa | 410t/t |

| Chilled Water | Water Inlet7℃, Water Outlet12℃ | 160×104KJ/t |

| Electric | 380V 50Hz | 250KWH/t |

| Waste Water | Ethanol 0.03%, Acidity 0.25%, COD5000ppm, BOD2000ppm | 5t/t |

| Exhaust Gas | Acetaldehyde≤0.1%, CO+CO2 ≤0.8%, H2+ CH4 ≤1.2%, H2O≤1%, N2≥96% | 1.143t/t |

| Acetaldehyde Yield | 99.7%wt |

Helipont is a solutions provider, implementing engineering, procurement, and construction (EPC) projects involving formaldehyde and formaldehyde derivative production operations. We focus innovative efforts on two areas: chemical equipment and chemical trade. Our silver catalyst formaldehyde production process and related equipment has been successfully implemented by some of the world’s premier chemical processors, helping them minimize operating costs and handle by-products safely and effectively.

Read More