- Home

- Technology & Plants

- Hexamine Plant

- Liquid Phase Hexamine Plant

Liquid Phase Hexamine Plant

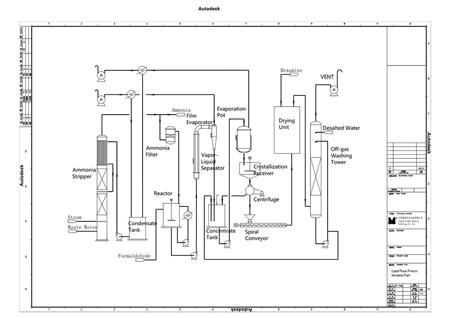

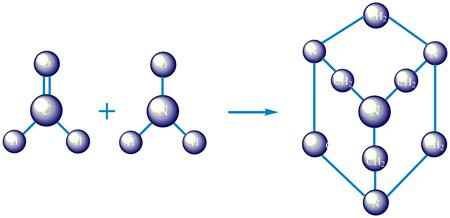

The liquid phase process uses a 37% formaldehyde solution and ammonium. The hexamine solution is then dewatered by evaporator and enters the centrifugation and drying device in order to obtain hexamine. This is an advanced, easy process. Because of the use of evaporation for dehydration, the crystal culture period is long and the urotropine particles are larger.

- Film-type evaporator

- Air-flow dryer

- Mother liquid filtration equipment

- Waste water

- Ammonia stripper

- Reactor

- Film Evaporator

- Vapor-liquid separator

- Concentrate tank

- Evaporation pot

- Crystallization receiver

- Centrifuge

- Spiral conveyor

- Desalted water

- The formaldehyde solution and ammonia gas react in the reactor, generating hexamine.

- Condense hexamine product to 60-65% concentration.

- Evaporation, condensation, centrifuge and drying of 65% hexamine.

- The process requires the use of a set of mother liquid filtration equipment because the liquid formaldehyde and condensation batch operations are used, often producing impurities and side reactions that affect product purity.

- For more information on the production process, please do not hesitate to contact us.

| Item | Superior | First Grade | Acceptable |

| Purity % ≥ | 99.3 | 99 | 98 |

| Moisture % ≤ | 0.5 | 1 | |

| Ashes % ≤ | 0.03 | 0.05 | 0.08 |

| Aqueous solution appearance | Acceptable | - | |

| Heavy Metal as Pb2+ % ≤ | 0.001 | - | |

| Chloride as Cl- % ≤ | 0.015 | - | |

| Sulphate as SO42- % ≤ | 0.02 | - | |

| Ammonium as NH4+ % ≤ | 0.001 | - | |

| Particular | unit | Index | Remark |

| Formaldehyde (37%) | t | 3.5~3.6 | |

| Ammonium (100%) | kg | 530~550 | |

| Circulating Cooling water | t | 250~300 | Water temperature≤25℃P≥0.4MPa |

| Steam | t | 7.0~8.0 | P≥0.4MPa |

| Electricity | kW·h | 180 | 380/220V 50Hz |

| Demineralized Water | t | 1~2 | As per standard of D.W. |

Projects Were Work on

Helipont is a solutions provider, implementing engineering, procurement, and construction (EPC) projects involving formaldehyde and formaldehyde derivative production operations. We focus innovative efforts on two areas: chemical equipment and chemical trade. Our silver catalyst formaldehyde production process and related equipment has been successfully implemented by some of the world’s premier chemical processors, helping them minimize operating costs and handle by-products safely and effectively.

Read More