- Home

- Technology & Plants

- Methylal Plant

- 99.5% Concentration Methylal Plant

99.5% Concentration Methylal Plant

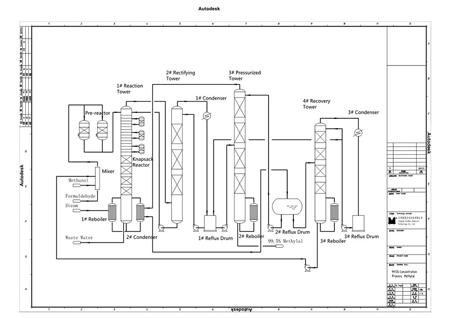

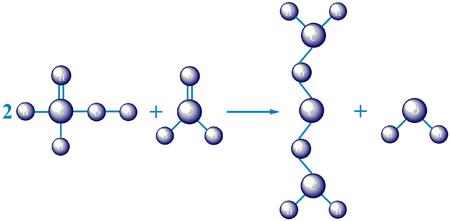

Due to the azeotrope from methylal, formaldehyde and water, normal rectification methods do not achieve a high methylal concentration. Based on the original process for normal concentrations, after researching, numerous tests and multiple technical designs, we successfully created a high concentration methylal process, ensuring the methylal purity reaches up to 99.5%.

- Condenser

- Reboiler

- Pre-reactor

- Reachion tower

- Rectifying tower

- Reflux drum

- Pressurized tower

- Condenser

- Produce 90% concentration methylal.

- Condense 90% concentration methylal to 99.5% concentration.

Annotation: for more information about the production process, please do not hesitate to contact us.

Consumption index| Item | Consumption quota | Remarks |

| Raw material and auxiliary material | ||

| Formaldehyde(37%) | 1.06t/t | |

| methanol(99.5%) | 0.84t/t | |

| Utilities | ||

| Industrial feeding water t≤25℃ | Intermittent flushing | |

| Circulating water t≤32℃,△t=8℃, Circulating quantity per hour | 115.2t/t | |

| Power(380V) | 60kWh/t | |

| Low pressure steam P=0.25MPa(G) | 750kg/t | |

| Medium pressure steam P=0.8MPa(G) | 550kg/t | |

Projects Were Work on

Helipont is a solutions provider, implementing engineering, procurement, and construction (EPC) projects involving formaldehyde and formaldehyde derivative production operations. We focus innovative efforts on two areas: chemical equipment and chemical trade. Our silver catalyst formaldehyde production process and related equipment has been successfully implemented by some of the world’s premier chemical processors, helping them minimize operating costs and handle by-products safely and effectively.

Read More