- Home

- Technology & Plants

- Formaldehyde Plant

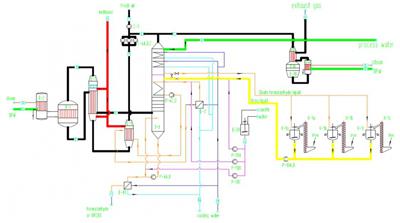

- Metal Oxide Process Formaldehyde Plant

Metal Oxide Process Formaldehyde Plant

The metal oxide process is a formaldehyde manufacturing process that uses iron molybdate as the catalyst. Helipont offers two reactor heat carrier types: a heat transfer oil and a molten salt.

- Less formaldehyde consumption

- Longer catalyst work period

- Formaldehyde concentration can reach 50%, while methanol content is less than 0.5%.

- Send compressed air to the methanol pre-evaporator.

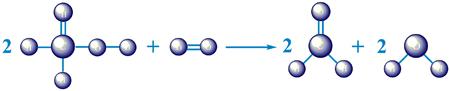

- Send gaseous methanol and air through the reactor that contains the catalyst for a reaction.

- Condense the formaldehyde gas from the reactor into a formaldehyde liquid.

Annotation: For more information on our production processes, please do not hesitate to contact us.

| Type | Index |

| Formaldehyde,Wt% | 37-57 |

| Based on 37%, | |

| Methanol,Wt% | < 0.8 |

| Formic acid,Wt% | < 0.03 |

| Consumption | |

| Methanol | 93% |

| Methanol,kg/MT* | 425 |

| Electricity (IBL),kW/MT* | 72 |

| CW - 10 deg C rise,m3/MT* | 50 |

| Steam consumed,kg/MT* | 0 (Net. prod.) |

| Steam output,kg/MT | 800undefined(1.2~2.0Mpa) |

Compare the metal oxide process and silver catalyst process on the economic front (assume 100,000 tons).

- Equipment: The metal oxide process requires a larger upfront investment in order to produce the same 55% formaldehyde solution.

- Steam output: metal oxide process, 800 kg/MT(2.0Mpa), while silver catalyst process 550 kg/MT(0.6Mpa). Assuming the steam unit price is $22/ton, metal oxide processes save $550,000/year.

- Methanol consumption: metal oxide processes save 20kg/TPA of methanol. Assuming the unit price of methanol is $430/t, metal oxide processes save $860,000/year.

- Service life of the metal oxide processing equipment is more than 50 years, which is almost 3 times longer than equipment used in the silver catalyst process. This means that using the metal oxide process saves up to $15,000/year in operation costs.

- Catalyst cost: The metal oxide process costs $260,000/year, while silver regeneration costs $20,000/year. Thus, the silver regeneration process costs $240,000 less per year

- Power consumption cost: metal oxide processes are higher than a silver catalyst process by about $440,000/year. (metal oxide process 70kwh/t, silver catalyst process 26kwh/t, electricity unit price $0.1/kwh)

- Using the metal oxide process saves about $740,000/year.

Projects Were Work on

Helipont is a solutions provider, implementing engineering, procurement, and construction (EPC) projects involving formaldehyde and formaldehyde derivative production operations. We focus innovative efforts on two areas: chemical equipment and chemical trade. Our silver catalyst formaldehyde production process and related equipment has been successfully implemented by some of the world’s premier chemical processors, helping them minimize operating costs and handle by-products safely and effectively.

Read More