- Home

- Technology & Plants

- Formaldehyde Plant

- Silver Catalyst Process Formaldehyde Plant

Silver Catalyst Process Formaldehyde Plant

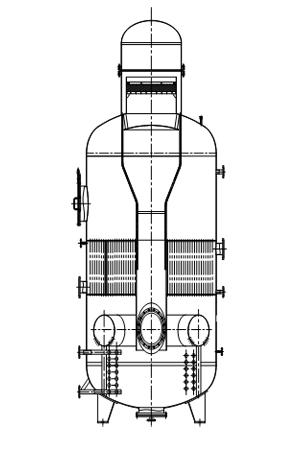

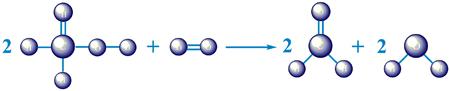

Currently, the silver catalyst process is the most common formaldehyde process, accounting for about 70% of the various formaldehyde production devices all over the world. According to Helipont’s experience, the improvement for this process is primarily divided into the following two types:

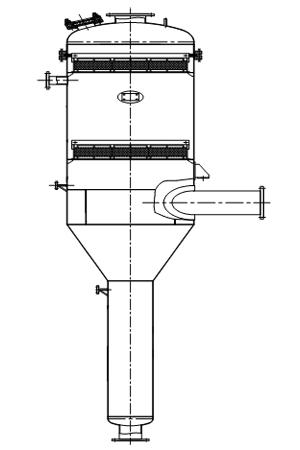

Production Process- Multifunctional Evaporator Formaldehyde Plant

The multi-functional evaporator process is the newest silver catalyst formaldehyde production process, and was independently researched and developed by the Helipont team. This patented process uses two specially designed absorption towers capable of producing 37-55% formaldehyde.

Read More - Formaldehyde Plants with Off-Gas Circulation

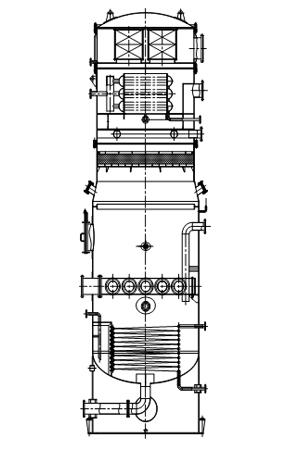

Formaldehyde plants with off-gas circulation are a traditional formaldehyde production technology. After educating ourselves on a number of reboiler processes from around the world, we optimized the process, equipment, and automation levels to simplify operations.

Read More

| Project | Normal process | Formaldehyde Plants with Off-Gas Circulation | Formaldehyde Plants with Flue-Gas Circulation |

| Methanol consumption | 445kg/t | 442kg/t | 438kg/t |

| concentration | 37-45% | 37-55% | 37-52% |

| Methanol content | ≤1.0% | ≤1.0% | ≤1.0% |

| Electricity consumption | 25kw | 28kw | 28kw |

| By-product steam | 600kg | 650kg | 650kg |

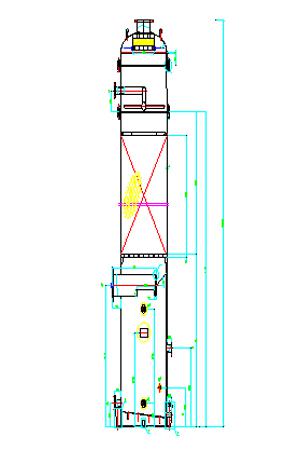

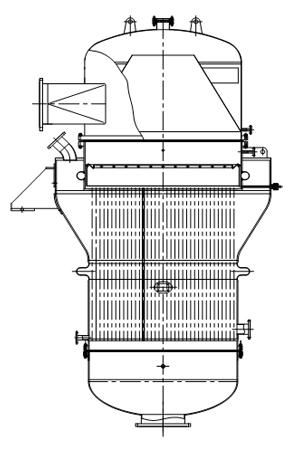

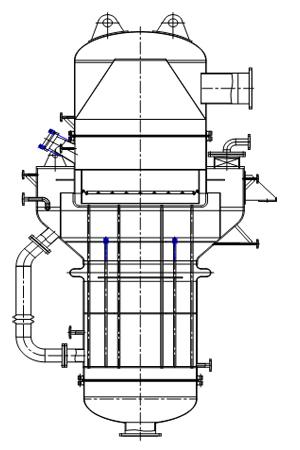

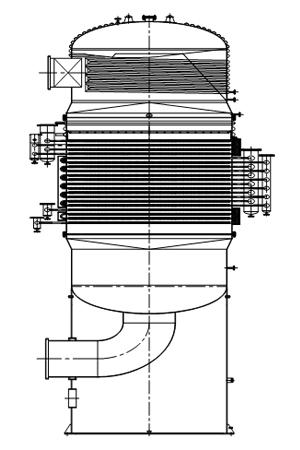

- Evaporator

- Oxidizer

- Absorption tower

- Off gas treatment

Helipont is a solutions provider, implementing engineering, procurement, and construction (EPC) projects involving formaldehyde and formaldehyde derivative production operations. We focus innovative efforts on two areas: chemical equipment and chemical trade. Our silver catalyst formaldehyde production process and related equipment has been successfully implemented by some of the world’s premier chemical processors, helping them minimize operating costs and handle by-products safely and effectively.

Read More